Ceramide Powder: The Ultimate Guide for Beauty Professionals

Ceramide powder is a huge step forward in the science of makeup ingredients. It gives beauty formulas unmatched stability and flexibility. This detailed guide covers everything beauty workers need to know about adding ceramide powder to skin care products, from comprehending its chemical structure to making the best formulations. Ceramide powder is an important ingredient that professional formulators all over the world know they need to make anti-aging, hydrating, and barrier-repair products that work.

Understanding Ceramide Science and Skin Biology

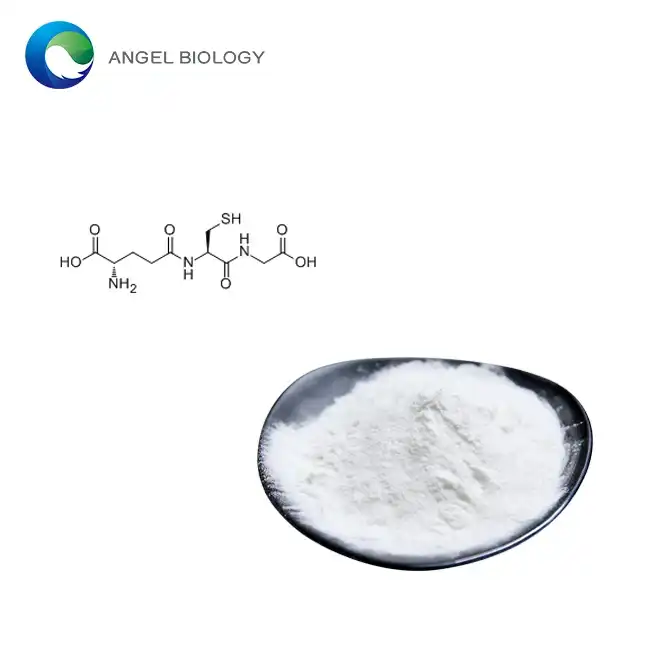

As basic building blocks, ceramides are found in the stratum corneum, the top layer of skin. These natural lipids make up about half of the skin's barrier. They form a complex network that keeps the skin properly hydrated and protects it from external stresses.

Ceramides are made up of molecules that fit together like puzzle pieces, creating tight connections between skin cells. This pattern makes a waterproof seal that stops wetness loss and keeps dangerous substances from getting deeper into the skin. The skin barrier gets a lot weaker when ceramide levels drop because of getting older, damage from the environment, or genetics.

pattern makes a waterproof seal that stops wetness loss and keeps dangerous substances from getting deeper into the skin. The skin barrier gets a lot weaker when ceramide levels drop because of getting older, damage from the environment, or genetics.

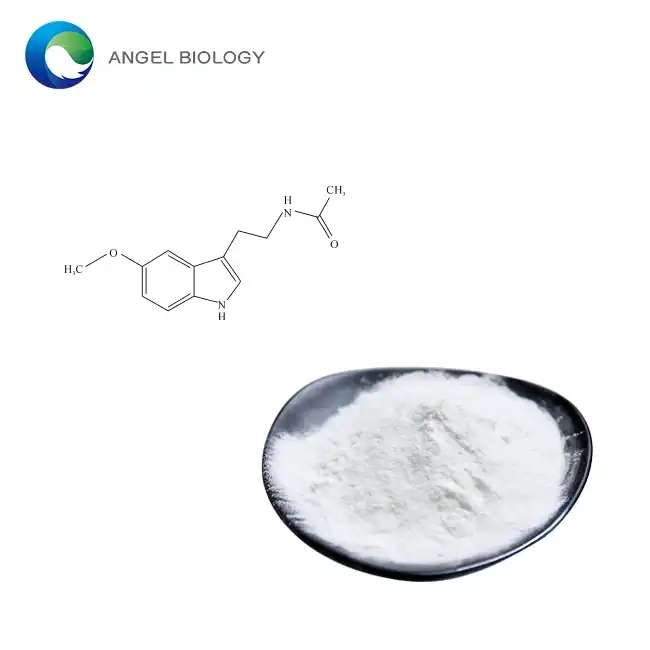

Around age 25, the body starts making less ceramide naturally. By age 40, amounts have dropped by about 30%. This decrease shows up as more dryness, sensitivity, and clear signs of age. Putting ceramide on the skin through cosmetics can successfully restore barrier function and improve general skin health by recovering reduced levels.

There are different kinds of ceramides that do different things in the skin tissue. Ceramide NP, which is one of the most common types, is very good at keeping water in. Ceramide AP helps make barriers stronger, and ceramide EOP keeps structures together. By knowing these differences, formulators can choose the right mixtures of ceramides for specific skin care products.

Types of Ceramide Powder and Their Applications

There are different kinds of ceramide powder used in the makeup business, and each one has its own benefits for different manufacturing needs. Ceramides that come from plants are natural, biocompatible, and in line with the clean beauty trend. Synthetic ceramides are better for large-scale production because they are more consistent and cost less.

In terms of makeup uses, Ceramide NP powder stands out as the most flexible choice. Because it stays very stable during processing, it's perfect for many types of products, like lotions, serums, and creams. The powder form makes doses accurate and takes away the worry that the ingredients will break down while being stored.

Brands that want to be seen as green like ceramide powders that come from plants. These ingredients are usually extracted from plants like wheat, rice, or other plants using special methods. Even though they are a little more expensive than manufactured options, people who care a lot about the environment really like plant-based ceramides.

Encapsulated ceramide powders are the newest and most advanced way to give ingredients. The process of wrapping keeps the delicate ceramide molecules from oxidizing and gives them controlled release mechanisms. This technology makes it easier for ingredients to get into the product and makes it last a lot longer.

Ceramide complex products mix different kinds of ceramide with lipids that work well together, such as cholesterol and fatty acids. These complex mixtures are a better match for the skin's natural lipid profile, making them better at repairing the barrier than treatments with only one ingredient.

Formulation Strategies for Maximum Efficacy

To successfully add ceramide powder, you need to pay close attention to the pH, temperature, and working conditions of the mixture. Ceramides work best in slightly acidic conditions, usually between pH 5.0 and 6.5. This range is close to the skin's normal pH and makes it easier for ingredients to be absorbed.

Controlling the temperature during production stops the breakdown of ceramide and keeps the powder's purity. Most ceramide powders can handle mild warmth up to 70°C, but long-term contact above this temperature may make them less effective. For sensitive mixtures, cold processing methods often work better.

Emulsification methods have a big effect on how well ceramide works in finished goods. Water-in-oil formulas are better at occluding, while oil-in-water emulsions are better at spreading ceramides. The choice relies on the feel you want and the skin benefits you want.

The size of the particles changes both how they look and how deeply they penetrate the skin. Micronized ceramide powders mix easily into mixtures and don't leave a gritty feeling. Larger particles may offer longer-lasting effects. Based on the needs of the product, formulators must find a balance between these factors.

Depending on the type of ceramide and the goals of the preparation, concentration values in finished goods are usually between 0.1% and 2%. Higher amounts may make the product less stable or irritate the skin of people who are sensitive to it. The best results are achieved by starting with smaller numbers and making changes based on efficiency tests.

Quality Specifications and Testing Standards

To make sure it always works right and is safe, professional-grade ceramide powder has to meet strict quality standards. For medicinal and high-end skincare uses, purity levels should be higher than 95%. Impurities that affect stability or cause skin reactions may be found in lower purity grades.

The amount of moisture in powder has a big effect on how stable it is and how long it lasts. Good ceramide powders keep the wetness level below 2% to stop microbes from growing and keep the powder's flowability. These qualities stay the same during keeping if you package them properly in cases that keep wetness out.

The way particles are spread out changes both the qualities of the product and how the skin feels. For best performance, professional providers offer thorough particle measurement, with sizes usually running from 10 to 100 micrometers. The behavior of different output batches can be predicted as long as the particle size stays the same.

Microbiological testing makes sure that a product is safe and follows the rules. Ceramide powders are put through a lot of tests to make sure they are free of bacteria, yeast, and mold. Throughout the supply chain, these high standards are kept up by clean factories and following the right way to handle things.

Long-term performance of finished goods can be predicted by testing their stability under fast circumstances. Good providers do a lot of research on how weather, humidity, and light contact affect things. It helps formulators figure out the best way to store their products and guess how long they will last.

Applications Across Beauty Product Categories

Ceramide powder can be used in many different types of beauty products, and each type has its own special barrier-supporting qualities. Ceramides are most often found in face creams, where they provide deep hydrating and anti-aging effects.

Serums use the concentrated power of ceramide powder to fix skin specifically. The light texture lets higher amounts of ceramides work without changing the look of the product. These items are especially popular with people who want professional-grade skincare goods.

Ceramide is a very useful ingredient for eye creams because the delicate skin around the eyes doesn't naturally have a lot of it. Ceramide powder is good for sensitive skin around the eyes because it is gentle and won't irritate the skin. Ceramide's ability to reduce wrinkles is especially helpful in anti-aging eye products.

Ceramide powder is used in body lotions and creams to moisturize and protect big areas of skin. Because powder types are cheap, they can be used for body care without breaking the bank. Ceramides are liked by consumers because they keep skin moist for a long time.

More and more cleansing products use ceramide powder to counteract the drying effects of detergents. Some ceramides are washed off when you wash your face, but the ones that are left on your skin continue to help it. This treatment works best with formulas for dry or sensitive skin.

Market Trends and Consumer Preferences

The global ceramide market is still growing quickly, thanks to more people realizing how important barriers are for health. When scientists learn more about how skin works, they need ingredients like ceramides that are backed up by evidence. Beauty experts say that customers are becoming more interested in goods that contain proven active ingredients.

According to the clean beauty trend, ceramide powders made from plants are better than manufactured ones. More and more, brands that market themselves as green or organic list plant ceramide sources. This choice goes beyond where the ingredients come from and includes environmentally friendly ways of getting them and preparing them.

Ceramide is mostly used for anti-aging purposes because older people want effective ways to deal with face changes that come with getting older. This group is very interested in the proven ability to recover young barrier function. In this area, buying choices are often influenced by what professionals say.

Ceramides are great for sensitive skin treatments, which is a rising market area. Ceramide-containing goods are popular with consumers because dermatologists suggest them as barrier-supporting. Beauty brands can get a lot of marketing help from this doctor support.

Consumers who want to save time and money like goods that combine ceramides with other active ingredients. Vitamin C and ceramide work together to protect against free radicals and help the skin's barrier function. When retinol and ceramide work together, they slow down the aging process and reduce the chance of pain.

Manufacturing and Supply Chain Considerations

To get ceramide powder reliably, you need to work with known sources who keep quality standards high. Different areas have different certification needs, but most places will accept factories that are ISO-certified. As markets grow around the world, following the rules gets harder and harder.

factories that are ISO-certified. As markets grow around the world, following the rules gets harder and harder.

The way ceramide powder is stored has a big effect on how stable and effective it is. Cool, dry places keep powder from breaking down and keep its ability to move. When material is rotated properly, fresh items always make it to the production lines.

After recent world problems, supply chain stability became more important. Diversified supply networks protect against problems with a single source. Carrying costs and supply guarantee are balanced by strategic stockpile management.

Costs include more than just the price of the ingredients themselves. They also include the costs of sending, storing, and handling them. Buying in bulk can save you money, but you need to make sure you have enough store space and a way to keep track of your goods.

Quality assurance plans must include testing of arriving ingredients, tracking of the process, and checking of the end product. These methods make sure that quality is always the same and that they meet the rules in all places.

Conclusion

Today, ceramide powder is an important part of many beauty products because it helps protect the face and works well in many different types of products. Beauty experts can make successful goods that meet customer goals if they understand ceramide science, recipe requirements, and quality standards. As the market for beauty chemicals based on proof grows, ceramides become important parts of competing product lines. To be successful, you need to carefully choose your suppliers, use the right preparation methods, and stick to quality standards that guarantee stable performance and customer satisfaction.

Partner with Angelbio for Premium Ceramide Powder Solutions

Angelbio has become a top company that makes ceramide powder by blending 18 years of research and development experience with cutting-edge production tools. Our cutting-edge technologies for separation and processing give you pharmaceutical-grade ceramide powder that meets the strictest manufacturing needs. If you are a beauty professional looking for a trusted ceramide powder provider, you can email our technical team at angel@angelbiology.com to get full product specs and help with unique formulations.

References

1. Coderch, L., López, O., de la Maza, A., & Parra, J.L. (2003). Ceramides and skin function. American Journal of Clinical Dermatology, 4(2), 107-129.

2. Meckfessel, M.H. & Brandt, S. (2014). The structure, function, and importance of ceramides in skin and their use as therapeutic agents in skin-care products. Journal of the American Academy of Dermatology, 71(1), 177-184.

3. Sahle, F.F., Gebre-Mariam, T., Dobner, B., Wohlrab, J., & Neubert, R.H. (2015). Skin diseases are associated with the depletion of stratum corneum lipids and stratum corneum lipid substitution therapy. Skin Pharmacology and Physiology, 28(1), 42-55.

4. Panchal, A., Patel, S., Vadgama, N., & Mehta, T. (2016). Ceramides: The latest research and therapeutic approach for various skin disorders. European Journal of Pharmaceutical Sciences, 94, 172-180.

5. Borodzicz, S., Rudnicka, L., Mirowska-Guzel, D., & Cudnoch-Jedrzejewska The role of epidermal sphingolipids in dermatologic diseases. Lipids in Health and Disease, 15(1), 13-25.

6. Yang, L., Mao-Qiang, M., Taljebini, M., Elias, P.M., & Feingold, K.R. (1995). Topical stratum corneum lipids accelerate barrier repair after tape stripping, solvent treatment, and some but not all types of detergent treatment. British Journal of Dermatology, 133(5), 679-685.