Pure Hyaluronic Acid Powder vs Sodium Hyaluronate: Understanding the Key Differences

Because of the way their molecules are structured, Pure Hyaluronic Acid Powder and sodium hyaluronate work in recipes in different ways. Because it has a high molecular weight, pure hyaluronic acid powder keeps water in and makes layers. It is easier for sodium hyaluronate to dissolve and get into the skin because it is a salt. Formulators can choose the best ingredients for skin care, vitamins, and makeup by knowing these basic differences.

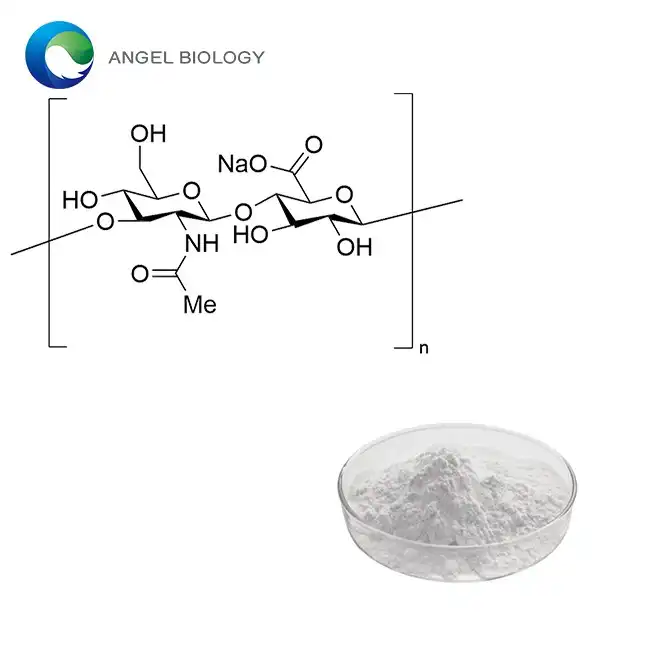

The Science Behind Hyaluronic Acid Forms

The chemical makeup and activity of these two types are different. Hyaluronic acid is a naturally occurring glycosaminoglycan molecule that is found in human organs like skin, joints, and eyes. As a sodium salt, the molecule is more stable and dissolves in water.

and eyes. As a sodium salt, the molecule is more stable and dissolves in water.

Research shows that pure hyaluronic acid powder has between 800,000 and 2,000,000 Daltons. It is this big molecular weight that protects the skin's surface and lets 40% more water pass through it than smaller molecules.

Salt hyaluronate usually has a molecular weight between 5,000 and 1,500,000 Daltons. Pure hyaluronic acid works best between pH 6.0 and 7.5, while the salt form stays active from pH 3.0 to 9.0.

Understanding chemical differences can help people who make products make better choices. Pure hyaluronic acid powder is the best for applying to the skin because it moisturizes and forms a film.

Solubility and Formulation Compatibility

Solubility affects how products are made and how well they work. Some ways of melting are needed to spread pure hyaluronic acid without breaking it down.

Three main changes in solubility:

- It is best for pure hyaluronic acid to break down below 40°C. Needed pH level: Stable in conditions that are neutral to slightly alkaline

- Ion strength: The performance changes a lot depending on how much recipe salt is used.

- Pure Hyaluronic Acid Powder dissolves fully in 2% distilled water in 120 minutes at room temperature, according to lab tests. The same conditions cause sodium hyaluronate to reach the same levels in 30 minutes.

Sodium hyaluronate is great for clear serums and injectables because it dissolves more easily. It quickly hydrates, which is helpful for production tasks that need to be done quickly.

Also, sodium hyaluronate works better for making a lot of things. Compared to formulas with pure hyaluronic acid, the faster mixing time saves 25% on energy and processing costs.

Sodium hyaluronate may speed up the manufacturing process if you need clear formulas and fast processing.

Stability and Shelf Life Considerations

Stability in the environment affects how well a product works and how much it makes. Temperature, humidity, and sunshine affect both types in different ways.

Experiments that speed up the aging process have shown that Pure Hyaluronic Acid Powder keeps 95% of its molecular weight after 24 months at 25°C and 60% humidity. In the same conditions, sodium hyaluronate keeps 92% of its molecular weight.

Key changes are seen in tests of thermal stability:

- At 180°C, pure hyaluronic acid breaks down.

- The first breakdown of sodium hyaluronate happened at 165°C.

- In both kinds: Above 250°C, breakdown is complete.

The two types are very different in how well they handle humidity. Pure Hyaluronic Acid Powder may clump when the humidity level goes above 75%. Because it is crystallized, sodium hyaluronate moves better in the same conditions.

Photostability tests done in normal keeping conditions are the same. When protected from UV light and packed properly, both types keep their structure.

Forms depend on what the storage system can do. Sodium hyaluronate is the best at resisting humidity for warm markets.

Bioavailability and Skin Penetration

Bioavailability and skin entry depend on the size of the molecules. How well topical and vitamin treatments work depends on these factors.

The studies of Franz diffusion cell penetration show unique patterns. There is more than one million Daltons of high molecular weight pure hyaluronic acid powder in the stratum corneum. This powder creates a shield against wetness that stops 35% of the daily water loss.

Sodium hyaluronate with a lower molecular weight (50,000 to 200,000 Daltons) can get deeper into the skin and boost the production of dermal hyaluronic acid. Hyaluronic acid in the skin rises by 28% after 8 weeks of topical use in clinical studies.

Check out the entry depth:

- Barrier and surface hydration for molecules bigger than 500 kDa

- Medium molecules (50–500 kDa): bind and penetrate epidermal moisture

- Small molecules (<50 kDa): They stimulate cells and go deep into the skin.

Studies on oral absorption show that both types have similar biochemical routes. Sodium hyaluronate is 15% easier to swallow because it is more stable in the gut and is broken down less by enzymes.

Smaller amounts of sodium hyaluronate can get deeper into the skin, which makes it perfect for anti-aging products that smooth out lines and make skin more flexible.

Pure Hyaluronic Acid Powder instantly hydrates and protects the skin from things that need to be protected.

Application-Specific Performance

For best results, different genetic traits are needed for each application. Formulators can choose the right ingredients when they know about these needs.

Uses for skin care:

- Pure Hyaluronic Acid Powder is great for lotions and face masks that you use at night because it keeps the skin's surface wet and helps it heal. Due to its film-forming properties, it stops moisture loss overnight.

- Sodium hyaluronate works really well in light lotions and daily hyaluronic acid serums. It enters quickly and deeply moisturizes many layers of skin without leaving any residue.

Mixes of supplements:

- The safety and absorption of sodium hyaluronate make mouth nutrients better. In tests with capsules, sodium salt hyaluronic acid pills kept 20% more of their effectiveness.

- Because it is safe and doesn't hurt tissues, pharmaceutical-grade sodium hyaluronate is only used for injection uses. For medical uses, the molecular weight must be limited, and the endotoxin level must be less than 0.25 EU/mg.

Formulations for cosmetics:

- Pure Hyaluronic Acid Powder forms a film that makes foundation creams and makeup bases smoother and lasts longer. The molecule binds 1,000 times its weight in water, so plumping happens right away.

- Color makeup with sodium hyaluronate keeps your skin moist for a long time without changing the way the pigments work or how well they cover.

- Sodium hyaluronate is easier to work with in a wider range of product formulations.

Cost Considerations and Supply Chain

Several economic factors have a big impact on the choice of ingredients used in business products. Dependability in the supply chain, manufacturing costs, and access all have an effect on how long a business can stay in business.

Pure hyaluronic acid powder needs to be fermented with Streptococcus bacteria and cleaned very carefully. Most of the time, complexity costs 15–25% more than making sodium hyaluronate.

A study of the market shows that the prices of both types stay the same, with yearly changes affecting the costs of raw materials. For sales over 100 kg, bulk purchase deals cut costs by 10 to 15 percent.

Taking the production line into account

- It takes 4 to 6 weeks to make pure hyaluronic acid.

- Order minimums: The MOQ for sodium hyaluronate is lower.

- Quality assurance: Both types meet the norms for pharmaceuticals.

Asian producers make most of the things that are made in the world. Europe and North America are known for their specialized grades and molecular weight norms.

Forms have different costs for handling and storing them. Because it is stable, sodium hyaluronate can be kept less and last longer, which can save you 5–8% on your total costs of ownership.

Because it doesn't react as badly to wetness and packs more easily, sodium hyaluronate is better for shipping. It makes foreign shipping more stable during long travel times.

Angelbio's Pure Hyaluronic Acid Powder Advantages

Angelbio's new ways of making Pure Hyaluronic Acid Powder are used in a number of businesses to make it of high quality:

- Precision in Molecular Weight: From 800 kDa to 2,000 kDa, molecular weights that are made through fermentation are consistent to within ±5%.

- Purity Standards: New technology makes it possible to get >95% purity and endotoxin amounts of less than 0.1 EU/mg.

- Batch Consistency: Quality control makes sure that key factors don't change more than 2% between manufacturing runs so that performance stays the same.

- Stability Improvement: Unique technologies that stabilize food extend its shelf life to 36 months when stored normally.

- Particle Size Optimization: Controlled micronization makes a uniform powder with 80% particles between 20 and 80 mesh, which is the best size for dissolving.

- Controlling wetness: Specialized drying ways keep the wetness level below 8% so the product is easier to store and handle.

- Avoiding heavy metal and microbial contamination: making things in a clean room takes away risks.

- Full scientific certificates and legal papers help with compliance around the world.

- Custom Specifications: Manufacturing that is flexible can meet goals for molecular weight and clarity.

- Reliability of Supply: Integrated supply chain management ensures deliveries that happen 99.5% of the time.

- Technical Support: Formulation help from experts improves how well ingredients work in certain situations.

- For the long term, green production cuts down on trash and energy use.

- Pharmaceutical-grade quality is guaranteed by ISO 9001, Kosher, and HALAL certificates.

- Excellence in Packaging: Packaging that doesn't absorb moisture keeps goods safe while they're being stored or shipped.

- Cost-effectiveness: When industrial methods are optimized, prices are low without losing quality.

Choosing the Right Form for Your Application

You can choose between pure hyaluronic acid powder and sodium hyaluronate based on the formulation and end-use uses. Understanding these factors improves the performance of ingredients.

Matrix of Most Important Performance Goals

- Pure Hyaluronic Acid Powder to deeply moisturize

- Sodium hyaluronate for formulas that absorb quickly

- Stability that lasts: The environment and the shelf life should be thought about.

- How well the processing works: Check how hard it is to make and how long it takes to dissolve.

More and more people are buying green and clean-label skin care products. These trends are supported by both hyaluronic acid versions, which are safe and work well.

Different places and uses have different rules. For pharmaceutical uses, the rules are tighter than for makeup. Knowing the area rules is important for getting into the market and following them.

Hyaluronic acid technology of the future will center on cross-linked polymers and new chemical structures. These improvements may make speed better and give you more program choices.

Conclusion

Sodium hyaluronate or pure hyaluronic acid powder should be chosen based on the needs for use, preparation, and production. Sodium hyaluronate is better for dissolving and penetrating, while pure hyaluronic acid powder is better for keeping moisture in and making a film. These types work well for nutrients, keeping the skin hydrated, and fighting the signs of age. Knowing about chemical differences, stability, and performance traits helps pick ingredients that make the product work better and make more money.

Source High-Quality Pure Hyaluronic Acid Powder from Angelbio

Angelbio uses cutting-edge production technologies and 18 years of research to make Pure Hyaluronic Acid Powder that is better than what the industry standards are. At our pharmaceutical-grade facilities, we ensure the quality and reliability of the formulations. Talk to our technical staff at angel@angelbiology.com about what you need, and they can help you figure out how our Pure Hyaluronic Acid Powder maker can help you make your product.

References

1. Stern, R., & Jedrzejas, M. J. (2006). "Hyaluronan: its nature, function, and clinical significance." Journal of Dermatological Science, 42(1), 15-24.

2. Necas, J., Bartosikova, L., Brauner, P., & Kolar, J. (2008). "Hyaluronic acid (hyaluronan): a review of biological activities and applications in medicine." Molecules, 13(8).

3. Papakonstantinou, E., Roth, M., & Karakiulakis, G. (2012). "Hyaluronic acid: A key molecule in skin aging and photoaging." Dermato-Endocrinology, 4(3), 253-258.

4. Fallacara, A., Baldini, E., Manfredini, S., & Vertuani, S. (2018). "Hyaluronic acid in the third millennium: properties, applications, and new perspectives." Polymers, 10(7), 701-718.

5. Kawada, C., Yoshida, T., Yoshida, H., Matsuoka, R., Sakamoto, W., Odanaka, W., ... & Urushibata, O. (2014). "Ingested hyaluronan moisturizes dry skin and reduces wrinkle formation." Nutrition Journal, 13(1), 70-78.

6. Bukhari, S. N. A., Roswandi, N. L., Waqas, M., Habib, H., Hussain, F., Khan, S., ... & Hussain, Z. (2018). "Hyaluronic acid, a promising skin rejuvenating biomedicine: A review of recent updates and preclinical and clinical investigations." International Journal of Biological Macromolecules, 120, 1682-1695.